|

Workshop Tools & Techniques |

| Brass Home Page |

| Mouthpieces |

| Mutes |

| Restorations |

| Brass Links |

|

|

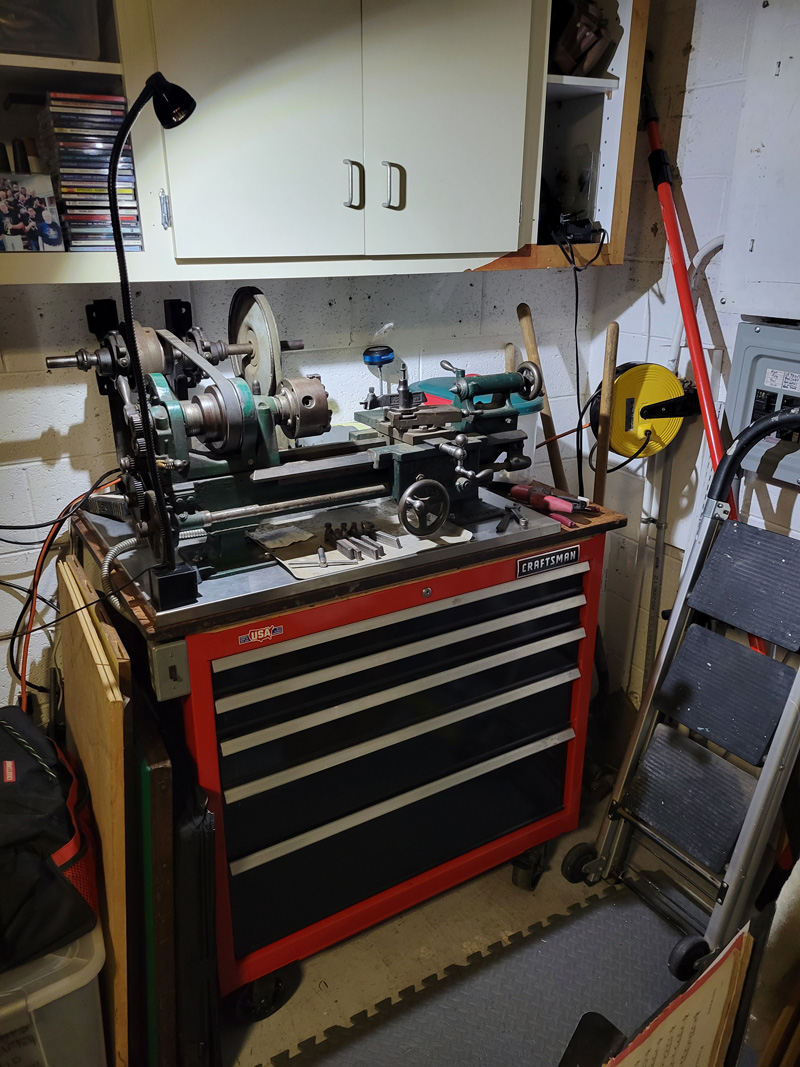

Since I have been doing brass restorations for over twenty years now, I thought that I would share some photos of tools that I have been using or making. Having no budget for this hobby, I have been learning how to be creative in making the tools needed. Occasionally I do make a little profit when selling a horn and sometimes use that to buy real tools from Ferree's. The much smaller Florida workshop in 2023. I used to have an 18'x18' building up north but now have reduced that to the back wall of the garage. Organization is essential.

The metal lathe. I acquired this many years ago from a friend who was a hobby machinist upgrading to a newer lathe. He called back a year later and wanted to buy it back! This was made by Dalton about 100 years ago and still going strong.

Hammer assortment - one never has enough.

When I first started getting into repair, I made this wall-mounted holder to fit a variety of rods. This seemed quicker and easier than putting them in a vise every time. This photo shows one of Ferree's tapered shafts which I welded to a common pipe fitting. The lower wall mount is for stability and spreading out the pressure needed for dent rolling.

Here are the various rods I use in the wall fixture. Some are straight rods found at the hardware store. The second one has an end made from the plastic hub from a wheelchair. This has two roller bearings and is great for smoothing out bell flair dents. The hard plastic won't damage the finish. The third one has a ball threaded on the end which is good for pushing dents out of a bell.

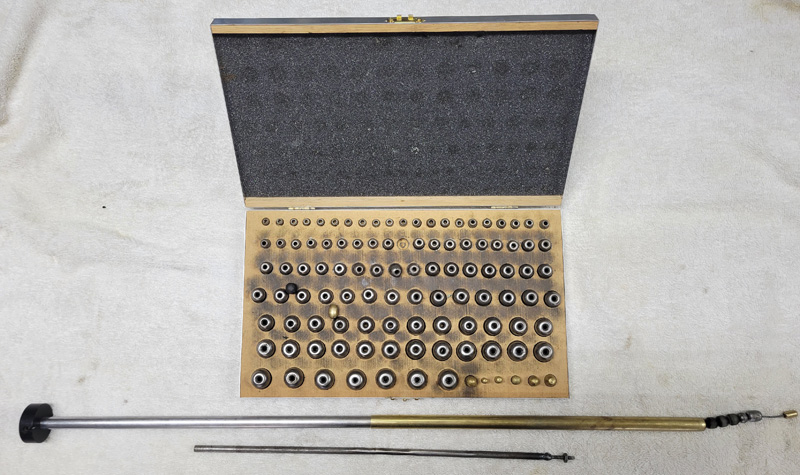

Here's my assortment of dent balls from Ferree's Tools. I've had to replace the cable in the ball holder only once in over 20 years. The bottom rod is used for lead pipes in trumpets. I mount the end in the vise, insert the lead pipe over this with the inlet end first, then add a dent ball on the threaded end. This can be done with the lead pipe on or off the trumpet.

Some burnishers and other tools. I made the top roller from scrap parts and a plastic wheel made on the lathe. The rings at the bottom work much better.

Pliers and other hand tools. The Ferree's expanders on the left are a recent purchase and much needed to adjust third valve slides and loose slide tubes. Third from the right are pliers sold as slide removers but I have found that I rarely use them for this purpose since they can too easily damage the ferrule. I often use them with the piece of rubber to remove valve caps and stems. For really stubborn stuck slides, I will take the slide apart, stick a dent ball into the end of the slide tube, then clamp down on the end with the small locking pliers on the right. This allows me to slowly work the tube both ways until it starts to move. The end of the tube gets marred up but this just goes back into the ferrule anyway, so just needs filing smooth again.

More assorted favorite tools. The bell mandrel works great with the curved burnisher to smooth out bells. The wood block with two dowels works perfect to hold a cornet or trumpet with the valves removed. The bottom wood handle has a small roller wheel made from a wheelchair hub. The long handle gives me leverage to roll out dents. I have given up on digital calipers and gone back to a high-quality German mechanical one. It's worth the cost.

Here's a great bell roller I just got from Ferree's that I have needed for many years. Just the right size for trumpet and cornet bells. I hope they never give in and buy junk from Asia. So far they are still US made.

My latest home-made tool is this dent roller made from a steel shaft and vintage pillow block bearings. Perfect for smoothing out bell flairs. I just mounted it to some old wood blocks in a T-shape and clamp it in the vise.

Another new home-made device is this bell holder. The two doors with a hole in the center are hinged on both sides and both inside surfaces are covered in 1/8" rubber sheet. This holds a cornet or trumpet for repair work or polishing and can be quickly installed in my vise. Here I am getting a trumpet ready for polishing.

A new and much-needed addition to the shop is this silver plating touch-up kit from Caswell. It works fantastic for small parts and I have even done complete mouthpieces with it. My only addition to the kit was a longer clip lead for better flexibility when using the wand.

|